The Cleanroom Laboratory is designed and maintained in accordance with the standards: ISO 14644-1: 1999, ISO 14644-1: 2015 and EU GMP (Guide to Good Manufacturing Practise).

In addition to the following laboratory equipment, important in the NBMC Cleanroom laboratory are also: cloakroom (room 0/6d), "clean" corridor (room 0/6f), "dirty" corridors (room 0/6g and 0/6h, serving as a technical back-up facility with necessary utilities) and airlock: two pressurized and one rotary (necessary for proper air circulation between clean zones, regulation of working pressures and ensuring an appropriate sanitary and sterile regime).

Cleanroom A (room 0/6a)

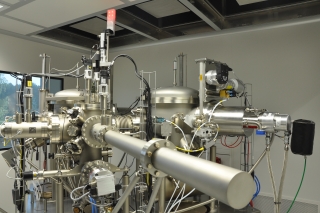

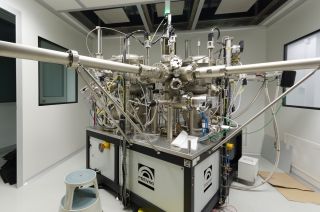

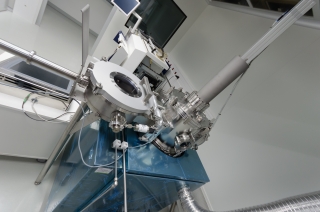

Ultra High Vacuum machine (UHV) for evaporation of materials

- Two growth chambers for the deposition of metallic layers (magnetic/nonmagnetic) with load-lock system

- UHV system equipped with cryogenic pumps (< 5x10-9 mbar)

- Electron gun (Telemark, 6 crucibles x 7 cm3)

- Ion gun (Tectra) to clean the substrate before evaporation process

- UHV manipulator:

- diameter of wafers: 0,2” – 4” (different shapes)

- substrate-vapor source angle: +/- 50°

- adjustable speed rotation of the substrate

- source rotation resolution: 1°

- substrate-vapor source angle: +/- 50°

- adjustable speed rotation of the substrate

- source rotation resolution: 1°

- Thickness gauge and evaporation rate measurement system

Bruker's Innova Atomic Force Microscope

Scan ranges up to XY= 90 mm2 , Z=7.5 mm and 5 mm2 Z=1.5 mm, unique closed-loop scan linearization system, atomic resolution.

Available modes: Contact Mode (air), Tapping Mode (air), PhaseImaging, Lift Mode, Magnetic Force Microscopy (MFM), Electrostatic Force Microscopy (EFM), Dark Lift, Lateral Force, Microscopy, Nano-Indentation, Scanning Tunneling Microscopy STM, Low Current STM, Conductive AFM, STM with EC, Contact and Tapping Modes with EC, Surface Potential, Piezoresponse, Scanning Capacitance, Force Modulation.

Available modes: Contact Mode (air), Tapping Mode (air), PhaseImaging, Lift Mode, Magnetic Force Microscopy (MFM), Electrostatic Force Microscopy (EFM), Dark Lift, Lateral Force, Microscopy, Nano-Indentation, Scanning Tunneling Microscopy STM, Low Current STM, Conductive AFM, STM with EC, Contact and Tapping Modes with EC, Surface Potential, Piezoresponse, Scanning Capacitance, Force Modulation.

Cleanroom B (room 0/6b)

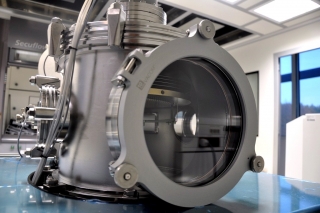

Reactive Ion Etching (RIE)

- RIE-system for the processing of up to 200 mm diameter wafers equipped with RF paralel plate plasma source

- Plasma source: 13.56 MHz, 600 W

- Load-lock system

- Gas lines: Ar, O2, SF6, CHF3

- Vacuum system: turbo molecular pump with banking pump

- System design is configured for downstream processes under the use of oxygen, fluorine or chlorine containing gases

- Standard recipes for etching processes of silicon containing materials (Si, SiO2, Si3N4)

- Homogeneity deviation: < +/- 3% over 100 mm substrates

- Repeatability of the process: < +/- 3% over 200 mm substrates

- SiO2 etching rate> 0.1 mm/min

Atomic Layer Deposition System (ALD)

- The reaction chamber "top-flow" (uniform, vertical gas flow orthogonal to the substrates), integrated in a vacuum chamber, heated

- Precursors sources:

- for solid state precursors

- for liquid precursors

- for solid/liquid precursors (up to 300°C)

- for liquid precursors

- for solid/liquid precursors (up to 300°C)

- Max. temperature of the proces: 500°C

- Size of wafers: up to 200 mm x 10 mm

- 3D substrates: up to 150 mm x 120 mm

- Gases: nitrogen, argon

- Load-lock system

Cleanroom C (room 0/6c)

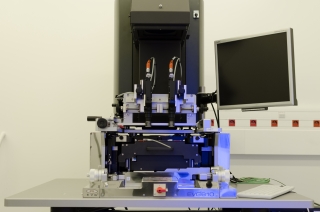

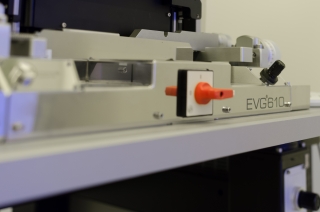

Mask aligner with spin coater

- Exposure modes: without a mask, the top centered, proximity (adjustable slots: 1-300 mm), "soft-contact" (adjustable pressure: 0.1-40N), "hard contact" (pressure regulation), "vacuum contact "(adjustable vacuum level)

- Precisely control table

- Digital microscope:

- manual

- high-resolution CCD camera

- 2 lenses (10x)

- digital zoom (4x)

- high-resolution CCD camera

- 2 lenses (10x)

- digital zoom (4x)

- Optical system (NUV)

- Substrate handles (Ø 100, 150 mm) and masks handles (Ø 125, 175 mm)

Cleanroom D (room 0/6d)

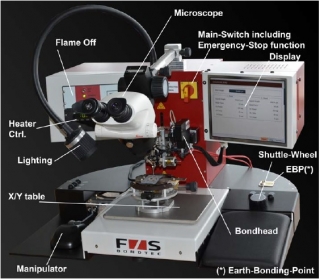

Wire Bonder 53xx BDA

- The bonder 53xx BDA (Ball Deep Access) from F&S Bondtec can be used as a thin-wire ultrasonic ball-wedge bonder for gold wires when software version 5310 is selected, or as a deep-access wedge-wedge bonder for aluminium and gold wires if software version 5332 is selected,

- Special design of the bondhead. This design makes the bonder highly versatile in terms of adaptability to material and application. Changing from one bond process to the other is a straightforward process involving merely the quick and easy replacement of the bonding wire and the bond tool,

- Ready for use as soon as the appropriate bonder software has been started,

- Ability to bond ribbon wires from 30 to 250 μm width,

- Operating temperature: 18-24.5°C,

- Relative humidity: 45% +/- 10% abs., no condensation,

- Supply voltage: 115 - 230 V AC,

- Voltage frequency: 50 - 60 Hz,

- Installed load: 230W,

- Noise emission: <70dBA,

- Vacuum: <300 mbar (outside Ø 6 mm).